Heating EDH Without Proper Airflow: Concerns & Solutions

Electric duct heaters (EDHs) are integral components of HVAC systems, ensuring reliable and efficient heating. However, challenges arise when dealing with variable air volume applications, where traditional pressure differential (PD) switches may fall short.

Neptronic addresses these concerns by introducing our unique Electronic Airflow Sensors (EAS) in conjunction with the Heater Electronic Controller (HEC) equipped with the optional BACnet communication protocol. This innovative integration not only enhances the performance of electric duct heaters but also provides a comprehensive solution for improved efficiency and reliability.

Challenges of Heating EDH Without Proper Airflow:

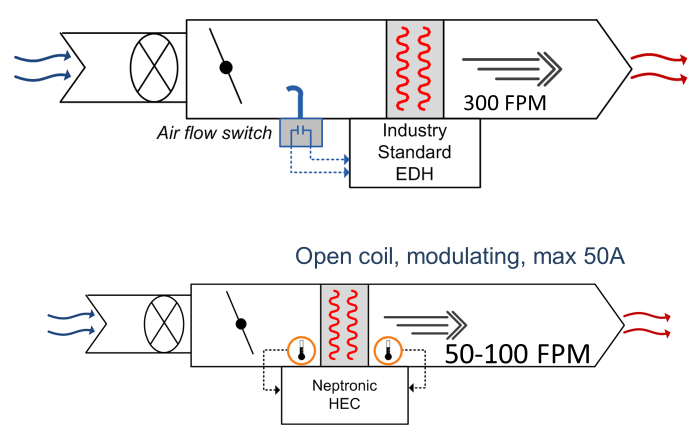

One of the primary concerns in heating EDH without proper airflow is the risk of overheating within the duct system. Fluctuating airflow can trigger the Pressure Differential (PD) switch to cycle on and off as pressure levels vary within the system. As airflow fluctuates, the PD switch responds by closing and opening, initiating the Electric Duct Heater (EDH) accordingly. This dynamic operation results in inconsistent heating of the EDH.

Moreover, if the airflow fails to reach the required threshold, a critical concern arises. The PD switch, designed to operate in conjunction with sufficient airflow, may not consistently engage. In such instances, the PD switch which is designed to operate at a minimum velocity of approximately 300FPM, faces limitations in VAV applications.

Without the necessary airflow to dissipate the generated heat, the Electric Duct Heater faces the risk of surpassing safe operating temperatures. This often results in unwanted heat shutdowns, risk of mechanical breakdown and discomfort in the designated zone.

Certification agencies mandate the inclusion of high limit thermal cutouts, both primary (i.e., automatic reset) and secondary (i.e., manual reset), to prevent overheating.

Introducing the Electronic Airflow Sensors (EAS):

To overcome the limitations of the PD switch, Neptronic offers Electronic Airflow Sensors (EAS) for their heaters.

These sensors, mounted at the inlet and outlet of the coil section, provide real-time temperature data to the Heater Electronic

Controller (HEC). The HEC constantly monitors airflow rates and adjusts the heat output based on actual conditions.

This enables the EDH to continue heating at low velocities, as low as 50 to 100FPM (depending on HEC model),

making it ideal for VAV applications.

BACnet's Role in Overarching System Control:

BACnet communication protocol serves as a bridge between the end user and the collective function of the EAS and the HEC.

This access to data allows the end user to make dynamic adjustments to electric duct heater operations, ensuring optimal

performance in varying conditions.

Furthermore, the BACnet enables users to have centralized control, simplifying the coordination of electric duct heaters

with other HVAC equipment. This centralized approach enhances overall system management, offering end-users an efficient

solution for their heating requirements.

The integration of EAS and HEC brings an extra layer of safety and energy efficiency (complemented by BACnet) to electric duct heaters.

In situations of low airflow, the HEC overrides the heat demand to prevent automatic cutouts from tripping.

The EAS allows for temporary heating cycles to detect delta T for proof of airflow before shutting down,

minimizing unnecessary heating during low airflow conditions. This not only ensures the safety of the system but also

contributes to energy savings.

Our EAS are available for our EDHs with the following standard conditions:

- Maximum width of 48”

- Maximum height of 40”

- Maximum current of 50A

- Open coil elements only

- Full modulating only

The EAS are compatible for duct air temperatures lower than 32C (90F).

Select the right technology for your application!