Last month, we covered the advantages of dual duct applications and where they can be used.

This month, we will touch base with the Neptronic controllers used for these types of applications.

Dual duct applications have two duct-works (hot & cold), so it also requires two controllers; a master & a slave.

Neptronic EVCBM14NIT2S represents the master controller and the EVCB14N represents the slave controller.

The TRL24 thermostat in this case is only connected to the master controller.

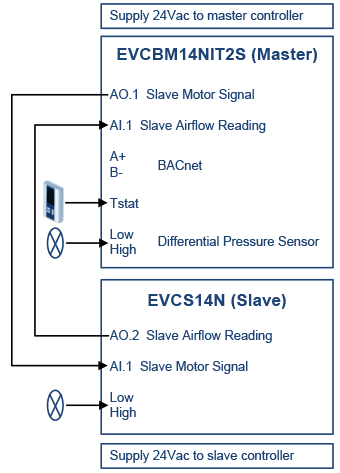

Master/Slave Wiring

As mentioned above, the TRL24 is wired to the master controller.

The master controller needs to send a signal to the slave controller to determine the airflow set-point required.

The slave will also need to give feedback to the master on the airflow reading.

There should only be one 24Vac power supply and it must be wired on both controllers. Note that the BACnet communication is optional.

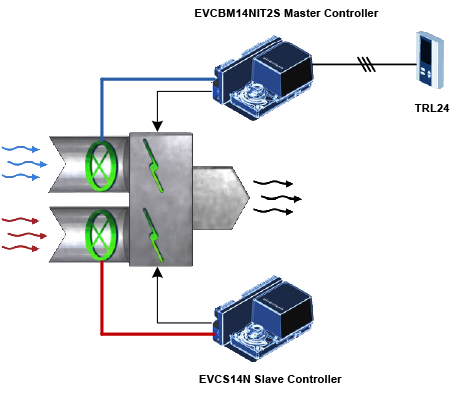

Airflow MonitoringBoth the master & the slave controllers are equipped with differential

pressure transducers to monitor airflow. There are three possible airflow configurations;

| Master (EVCBM14NIT2S) |

Slave (EVCB14N) |

Setting |

| Monitors Cold Deck |

Monitors Hot Deck |

Default |

| Monitors Cold Deck |

Monitors Total Deck |

Cfg_Pressure 2 Option is changed to Total |

| Monitors Hot Deck |

Monitors Cold Deck |

MSV.35 Cfg_Motor 1 Ramp is changed to Heating reverses monitoring configuration |

| Monitors Hot Deck |

Monitors Total Deck |

Cfg_Pressure 2 Option is changed to Total and

MSV.35 Cfg_Motor 1 Ramp is changed to Heating reverses monitoring configuration |

By default, the master controller monitors the cold deck and the slave controller monitors the hot deck.

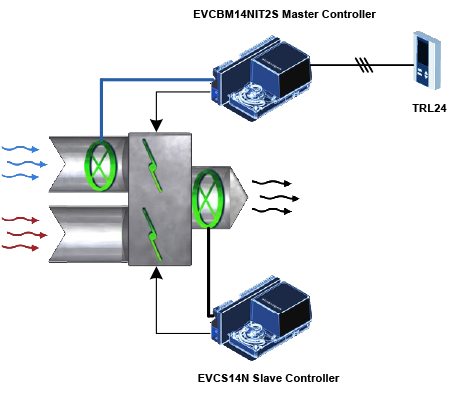

If BV.49 Cfg_Pressure 2 Option configuration is changed to Total then the master controller will still monitor the cold deck but the slave controller

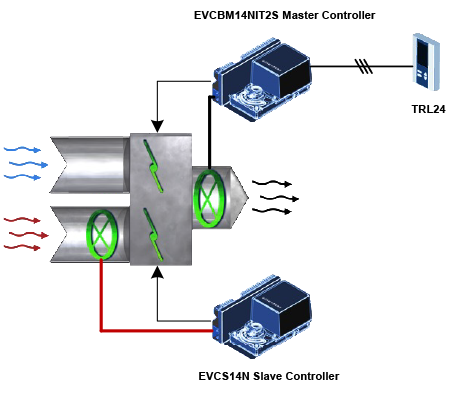

will now monitor the total deck. MSV.35 Cfg_Motor 1 Ramp configuration can be used to reverse the monitoring configuration; when set to Heating

(default Cooling), the master controller will now monitor the hot deck & the slave will monitor the cold deck. Usually, the engineer determines

the preferred configuration.

Cold & Hot Deck Monitoring

Cold & Total Deck Monitoring

Hot & Total Deck Monitoring

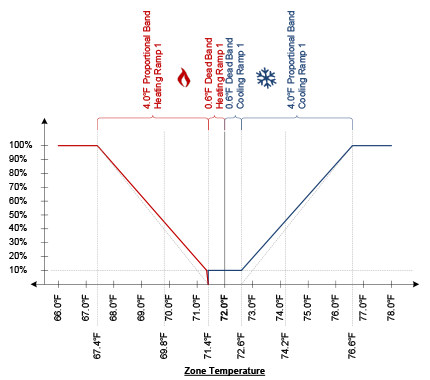

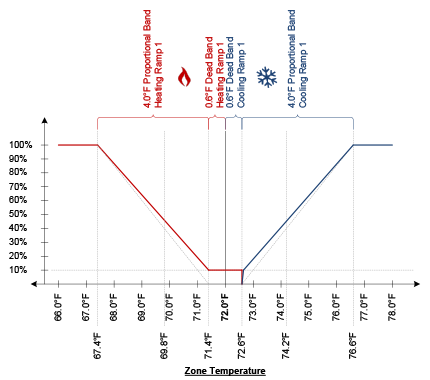

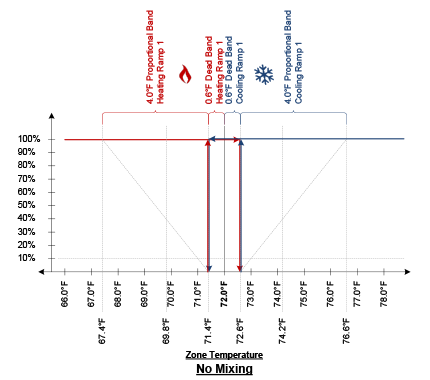

Cold & Hot Deck Sequence & OptionsIt is possible to use the dual duct box so that the cold & hot deck air will never mix.

This type of sequence is also called snap acting. AV.128 Cfg_Mix Air Dead Band configuration must be set to “0” to be able to achieve this.

On Temperature Decrease

On temperature decrease (from cooling proportional band to dead band);

As space temperature decreases, the cold deck damper modulates from its maximum to minimum airflow position.

Dead band operation (from cooling operation);

While in the cooling and heating dead band,

the cold deck damper remains at its minimum position until it reaches the limit of the heating dead band (71.4°F).

At this point, the cold deck damper will close and the hot deck damper will open to its minimum airflow position.

On temperature decrease (from dead band to heating proportional band);

As space temperature reaches the heating

dead band set-point (71.4°F), the cold deck damper closes and the hot deck damper opens to its minimum airflow position. If temperature keeps decreasing,

the hot deck damper modulates from its minimum to the maximum airflow.

On Temperature Rise

On temperature rise (from heating proportional band to dead band);

As space temperature increases, the hot deck damper modulates from its maximum to minimum airflow position.

Dead band operation (from heating operation);

While in the heating and cooling dead band, the hot deck damper

remains at its minimum position until it reaches the limit of the cooling dead band (72.6°F). At this point, the hot deck damper will close and the cold

deck damper will open to its minimum airflow position

On temperature rise (from dead band to cooling proportional band);

As space temperature reaches the cooling

dead band set-point (72.6°F), the hot deck damper closes and the cold deck damper opens to its minimum airflow position. If temperature keeps rising,

the cold deck damper modulates from its minimum to the maximum airflow.

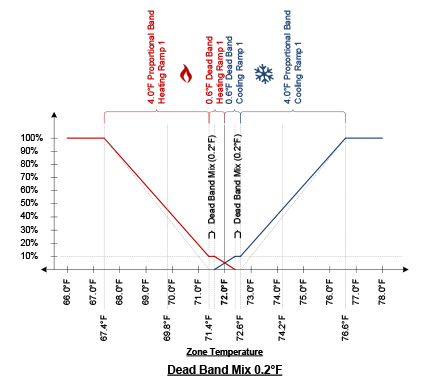

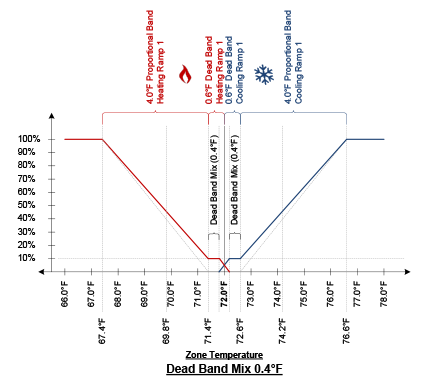

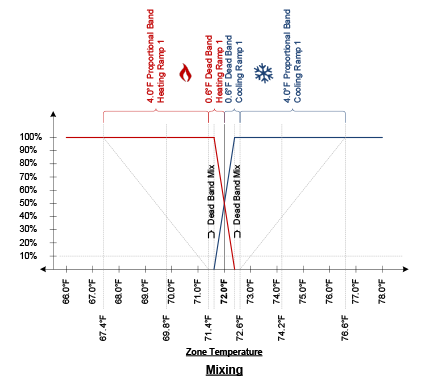

It is also possible to mix the cold & hot deck when in the dead band. This allows a more precise control when neither heating nor cooling is required.

In this case AV.128 Cfg_Mix Air Dead Band must be configured to 0.1˚C (0.2˚F) or 0.2˚C (0.4˚F). Note that the mixing band can be widened with the help

of the AV.22 Cfg_Heating 1 Dead Band & AV.42 Cfg_Cooling 1 Dead Band.

Cooling proportional band;

While in the cooling proportional band, the cold duct damper modulates from its

minimum to maximum airflow position.

Dead band mix of the cooling dead band;

While in the dead band mix of the cooling dead band, the cold duct damper

moves to its minimum airflow position. The hot duct damper is closed.

Mixing Band (between cooling and heating dead band mix);

While in between the two dead band mix, the cold & hot

duct dampers modulate to keep a minimum airflow. The minimum heating and cooling airflow can be set at different values.

Dead band mix of the heating dead band;

While in the dead band mix of the heating dead band, the hot duct damper

moves to its minimum airflow position. The cold duct damper is closed.

Heating proportional band;

While in the heating proportional band, the hot duct damper modulates from its minimum

to maximum airflow position.

The last option is to make the controller act as a constant volume using BV.48 Cfg_Constant Flow Option.

When disabled, the controller acts as a variable volume. Note that the controller still has the option to be the mixing type or the non-mixing type (snap acting).

Usually, when constant volume is used, the dual duct VAV box will be the mixing type.

This covers most of the configurations for the dual duct applications. Note that there are additional features such as adding baseboard reheat available.