How it works:

The impact of an energy recovery wheel within a ventilation system

There are a few terms used to describe an energy recovery wheel - it can be known as a heat recovery wheel; an enthalpy wheel and as a desiccant wheel. An energy recovery wheel

consists of a circular honeycomb matrix of heat-absorbing material, which is slowly rotated within the supply and exhaust air streams of an air-handling system. Most energy recovery devices

transfer heat (sensible) energy only. The enthalpy wheel allows both heat (sensible) energy and moisture (latent) energy to be exchanged. In most cases a matrix core material is coated with a

desiccant such as Silica gel or other molecular sieves to increase latent transfer.

|

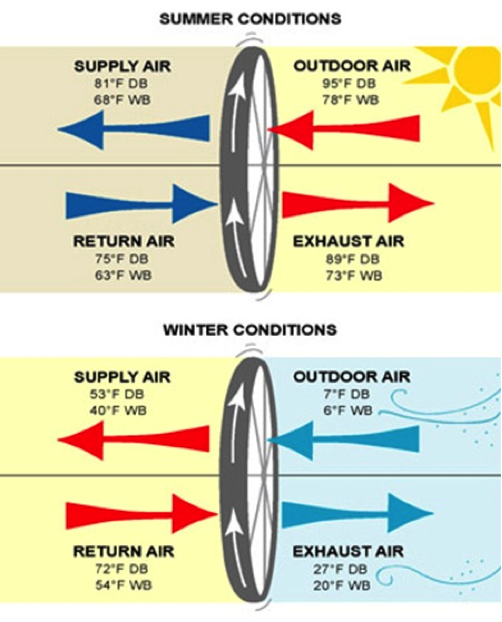

Example of a typical energy exchange through an enthalpy wheel.

An enthalpy wheel exchanges heat and humidity from one air-stream to another. Rather than discard used building air, an enthalpy wheel salvages useful energy and transfers it to incoming, fresh air.

This saves energy by reducing the need for cooling in the summer and heating in the winter.

Humidification load calculation using these winter conditions:

Assuming 2000CFM outside air and indoor conditions of 72°F / 30%RH

In this example, the calculated load is 35 lb/hr without the enthalpy wheel and 21 lb/hr with one. |

The enthalpy wheel rotates between the incoming fresh air and the exhaust air. Heat and moisture are given up to the wheel. When the space is in the heating mode, the heat and desirable humidity are used to pre-condition the incoming, cold, dry air. In the cooling mode, the incoming air is pre-cooled and dehumidified.

Just as the temperature is captured and released, so is the moisture (latent energy). This is accomplished by the desiccant coating of the wheel. The desiccant has a very strong affinity for water and an enormous internal surface area to bind the water to its surface. Since the opposing airstreams have different temperatures and moisture contents, the vapor pressures on their surfaces differ. This vapor pressure differential is the driving force necessary for the transfer of water vapor. The result is that cooler air is humidified and warmer air is dehumidified.

When calculating the humidification load, instead of using the outdoor air conditions, it is the supply air conditions (after the enthalpy wheel) that are required. The supply air temperatures are determined by the energy recovery wheel manufacturer. It is important to consider the maintenance of the enthalpy wheel as contaminants in the airstream can adhere to the surface of the wheel thus reducing the latent effectiveness by clogging the water-absorbing pores on the surface of the desiccant. Keep it clean for optimal efficiency!