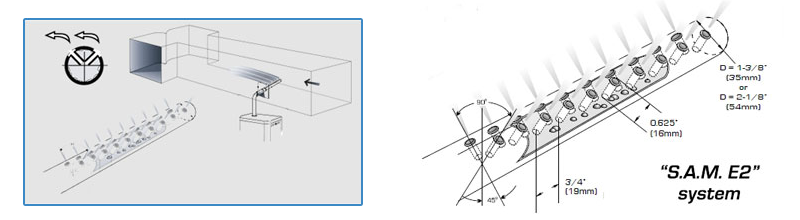

The S.A.M. E2 dispersion manifolds with 2 rows, 90⁰ configuration of the steam nozzles, allows significant reduction of the total length of the manifold for smaller duct size applications. The function of the nozzles is to prevent condensation from escaping to the duct. The accumulated condensation is channeled through the inclined steam dispersion tube back to the humidifier or the steam trap.